Your experts for the development and implementation of customized packaging solutions

Our Packaging Competence Center (PCC) with its team of seasoned experts supports you with your unique packaging requirements. With our know-how, we accompany you in every step of your project.

Whether you are looking for an original packaging solution, the optimization of an existing one, a tailor-made machine concept, or to maximize your machine’s performance, PCC develops and implements the ideal, tailored, and sustainable solution alongside you or for you.

Packaging material

Consulting

- Fiber-based material: from cardboard to medical grade paper

- Formable materials: plastic (rigid, soft, laminates), metal (aluminum) and composites in all shapes and designs

- Material from sustainable (incl. recycled) or plant-based sources

- Developing concepts for packaging solutions (PoC)

Additional materials

- Adhesive, lacquers and finishing coatings

Reference specification

- Consumables and further packaging elements such as booklets or leaflets

Network

- Access to a network of established expert partners and research facilities

Materials expertise

- Safe and reliable processing in terms of performance and quality

- Process optimization, e.g., for higher cycle rates, reduced material usage which deliver cost savings

Packaging design

Design

- Creating the design, including layouts and drawings

Consulting on package features

- Standard functions: opening mechanisms, inlays, product protection, child-resistant

- Customized functions: anti-theft protection, odor barriers

Consulting on design for manufacturability

- Maximizing machine output

- Ensuring high-quality packaging

Faster and more flexible

- Transition from concept to machine-produced using 3D prototyping to produce packages

- Manufacturing of small batches with original material

Technology and packaging process

Analysis and consulting on packaging processes

- Established standards

- Best Practices

- OEE optimization

New functions, technologies, and packaging processes

- Developing solutions based on proven modules

- Access to a large modular toolkit of qualified solutions, e.g., feeding and handling systems, labeling systems, control and inspection systems

Packaging solutions

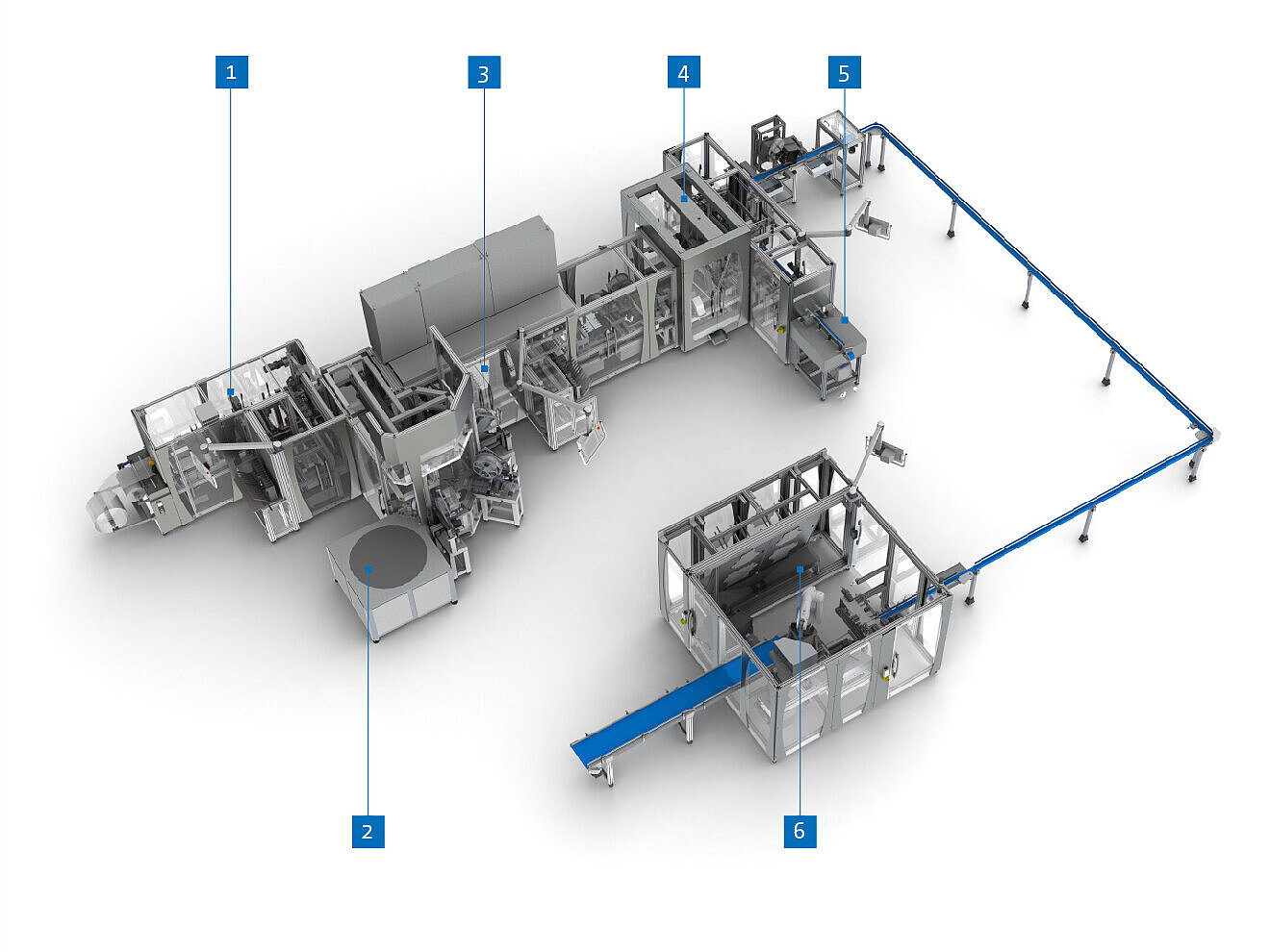

- Developing semi- or fully automatic packaging solutions

Digitization solutions

- Smart Production fore more efficient production processes

- Digital Twin – digital machine concept for design and simulation

Sustainability

Evaluation and comparison

- Comparing packaging solutions and concepts from a sustainability perspective

Life cycle assessment

- Analyzing and comparing the environmental footprint of a packaging concept using proven softwares

Developing optimization approaches

- Material selection, e.g., recycled materials

- Packaging design, e.g., Made-for-Recycling

- Packaging process, e.g., sealing edge

Creative, innovative, sustainable

Optimally designed for each project phase and customized to your needs.

Our team of more than 50 experts at KOCH and in the Uhlmann Group develop creative, innovative, and sustainable packaging solutions tailored to your wishes and requirements. Our extensive modular services, will perfectly match your needs. We look foward to discussing all necessary project steps with you in a free consultation, or, alternatively, in an "expert scoping session" or "machine data analytics" session.

Contact us today and we will help you find the best solution for your unique needs!

EXPERT SCOPING SESSION

- Free initial consultation

- In a non-binding consultation, we get to know each other, discuss your requirements, and advise you on which of our service packages best serves your needs

- 2 – 3 hours free consultation

- Digital or on site in Pfalzgrafenweiler

- Seasoned experts

- Individual consultation

- Optional: Scoping Assessment Report

MACHINE DATA ANALYTICS

- Free initial consultation

- In a non-binding consultation session, we will discuss your requirements related to software packages to increase machine efficiency. Subsequently, we will guide you on the next steps that best align with your project

- 2 – 3 hours free consultation

- Digital or on site in Pfalzgrafenweiler

- Seasoned experts

- Individual consultation

- Optional: Scoping assessment report

EXPERT WORKSHOP / TROUBLESHOOTING

- Our experts provide insights into your topic with content designed specifically for you, including in-depth analyses and a discussion session.

- Focused on issues such as sustainability, packaging materials, design, technology, and processes

- Further topics can be discussed on request

- Digital or on site in Pfalzgrafenweiler

- Workshop package with all supporting documents

- Qualified team of experts for the respective topics

SUSTAINABILITY ASSESMENT

- Our experts provide insights into demonstrating sustainability in packaging solutions and improving the ecological footprint

- Benefit from our comprehensive expertise in life cycle assessment or material recyclability

- Together we will identify your optimization potential and deliver tailor-made solutions.

- Detailed report for a screening life cycle assessment (sLCA)

- Evaluation report for all analyses performed

- Recommended methods for enhancing the sustainability and recyclability of your product

MATERIAL ASSESSMENT

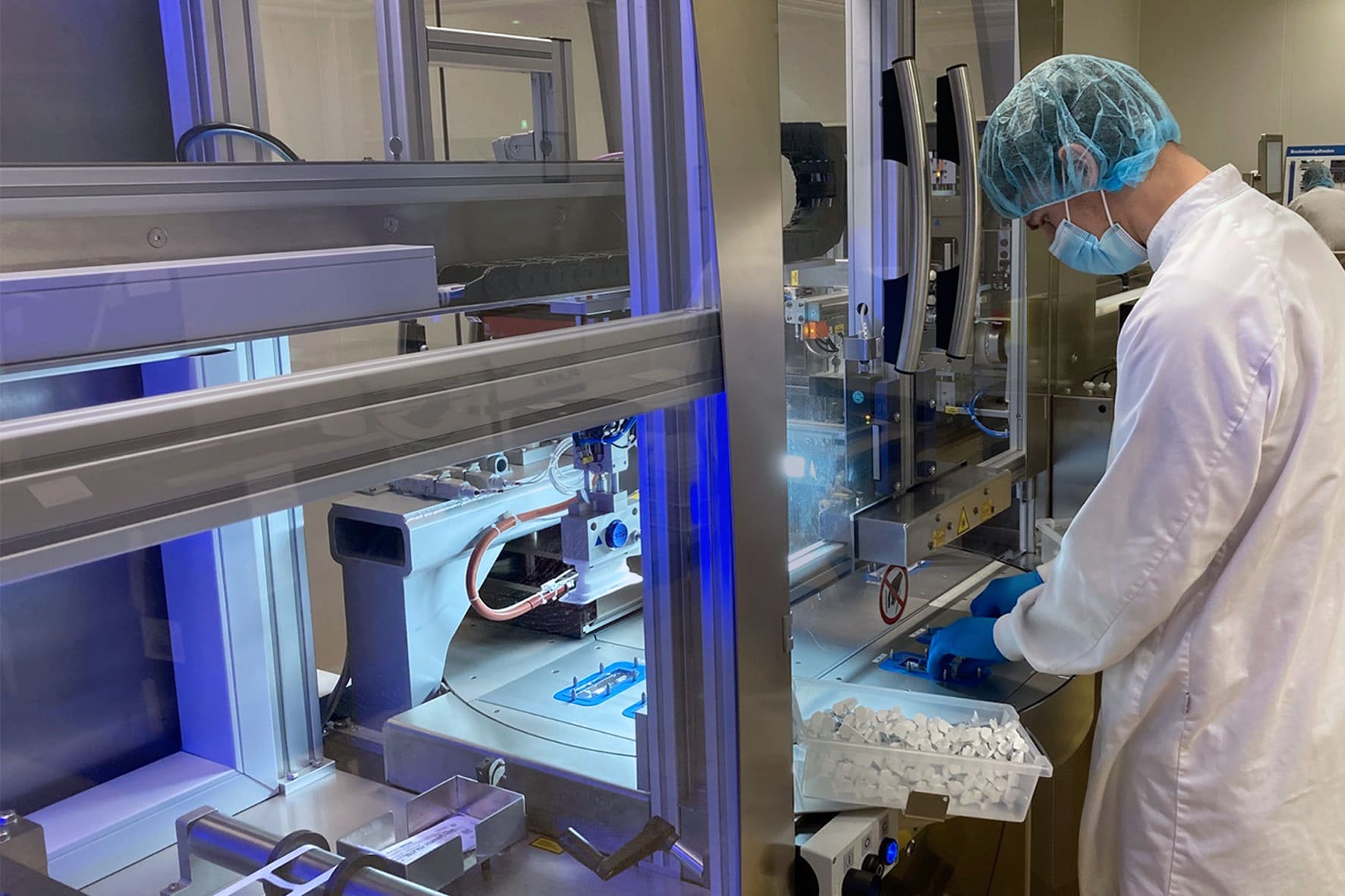

- Our experts carry out a proof of concept, check your material quality with regard to your target image, and assess issues such as thermoformability, sealability, printing options and other parameters. Benefit from our extensively equipped in-house KOCH machine shop with numerous tools for implementation

- Detailed test report including explanations

- Overview matrix on the processability of packaging materials

- Designs on customer request

PACKAGING DEVELOPMENT

- Our experts develop a new packaging design tailored to your wishes and specifications or customize the design according to your needs

- Initial samples can be created at an advanced stage in the packaging design phase using 3D printing processes

- Customized packaging development (e.g., using a 3D scanning process)

- Creation of packaging samples

- Packaging solution including a recommendation for the packaging material or creation of a photorealistic rendering

PACKAGING PROTOTYPING

- We produce your individual customer samples, and you benefit from our extensively equipped in-house KOCH machine shop with numerous tools. The product is not yet finalized? We can also manufacture samples without the product or lid material

- Rapid creation of individual customer samples

- Suitable for every product and packaging development stage

QUALIFICATION & VALIDATION

- Every industry has its own, unique packaging requirements. Our experts are familiar with the standards and requirements for the consumer products and healthcareproducts sectors and perform appropriate qualification and validation tests. Benefit from our know-how and lean processes

- Implementation of individual tests, also at external institutes on request

- Detailed test report including a comprehensive recommended action plan

Spanning an area of over 1,000 sqm, the Packaging Competence Center in Pfalzgrafenweiler offers a custom-fit infrastructure and an optimal working environment.

Over 50 experts at KOCH and in the Uhlmann Group make up our dedicated competence teams and assist our customers in finding the ideal solution. In Pfalzgrafenweiler you will find the following facilities:

CONSUMER PRODUCTS

From car parts to toothbrushes: packaging machines for consumer goods made by Koch. They are used in many different areas of the consumer goods industry, from packaging office supplies to the cosmetics & beauty sector.

HEALTHCARE

Our packaging machines for the HEALTHCARE sector are extremely versatile. They are used to produce blister packs for liquids such as ampoules and syringes, for solids such as tablets and capsules, or for various diagnostics such as dosimeters, reagent strips or rapid tests.

CONTACT LENSES

Whether individually packaged monthly lenses, daily disposable lenses in a multi-color blister pack, prescription or non-prescription tinted lenses, saline solution for contact lens storage or eye drops: KOCH blister machines and KOCH packagingLines meet the highest standards of efficiency – day after day and lens after lens.